Custom Hardware Solutions: When Standard Parts Won’t Cut It

Custom Hardware Solutions: When Standard Parts Won't Cut It

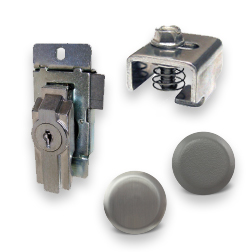

Custom hardware solutions refer to the design and development of hardware components that are tailored to meet specific needs or requirements. Unlike standard parts that are mass-produced for a broad range of applications, custom hardware is meticulously crafted to serve unique purposes, ensuring optimal performance and efficiency in its designated role. This tailored approach allows for the fine-tuning of hardware characteristics, such as size, weight, and material composition, to precisely fit the specific needs of a project.

Additionally, custom hardware solutions often involve a collaborative process between engineers, designers, and stakeholders to ensure that the final product aligns perfectly with the intended use case. This collaboration not only enhances the functionality and performance of the hardware but also provides opportunities for innovation and differentiation in the marketplace. By addressing specific challenges and requirements head-on, custom hardware can often exceed the capabilities of standard components.

Why Choose Custom Hardware?

Opting for custom hardware solutions can bring numerous advantages to the table:

Precision and Performance: Custom hardware is designed to meet exact specifications, leading to higher precision and improved performance in specialized applications. This precision can translate to enhanced reliability and efficiency, particularly in applications where accuracy is paramount.

Competitive Edge: Businesses can gain a competitive advantage by utilizing hardware that is specifically tailored to their unique requirements, thus optimizing operations. Custom hardware can also facilitate the development of proprietary technology, creating barriers to entry for competitors and establishing a unique position in the market.

Scalability and Flexibility: Custom solutions can be easily modified or scaled to accommodate future needs, providing long-term value. This flexibility allows companies to adapt to changing market conditions and technological advancements without the need for a complete redesign.

Furthermore, choosing custom hardware can lead to innovations that drive new product development and open up new markets. The ability to create hardware that precisely meets the needs of a niche market or application can lead to opportunities that standard solutions simply cannot offer.

When Standard Parts Won't Cut It

There are many scenarios where standard parts simply do not meet the requirements of a project or application. The limitations of off-the-shelf components become evident when projects demand more than what mass-produced parts can offer, particularly in terms of performance, integration, and design.

Unique Requirements

Certain industries, such as aerospace or medical devices, often have unique and stringent requirements that standard components cannot meet. These industries demand high precision, specific materials, or unique configurations that only custom hardware can provide. For instance, medical devices may require biocompatible materials to ensure patient safety, while aerospace components must withstand extreme conditions and comply with rigorous regulatory standards.

In these contexts, the ability to customize hardware ensures that all critical specifications are met, which is crucial for the safety, efficacy, and success of the end product. Custom hardware solutions offer the flexibility to incorporate unique features, materials, and design elements that standard parts cannot accommodate.

Advanced Technology Integration

In cases where cutting-edge technology is involved, integrating with standard hardware can be challenging or even impossible. Custom solutions allow for seamless integration with new technologies, ensuring compatibility and functionality. For example, emerging technologies such as IoT devices or AI systems may require specialized interfaces or processing capabilities that off-the-shelf components do not support.

Custom hardware can bridge the gap between existing systems and new innovations, facilitating smoother transitions and integration processes. This adaptability is essential for companies looking to stay ahead in fast-evolving technological landscapes, where the ability to quickly implement new technologies can be a decisive factor in maintaining competitive advantage.

Optimizing for Space and Weight

In industries like automotive or electronics, space and weight optimization is crucial. Custom hardware can be designed to fit specific dimensions or weight constraints, enhancing the overall product design and efficiency. This optimization can lead to increased performance, reduced energy consumption, and improved user experience, all of which are critical factors in competitive markets.

Moreover, custom hardware allows for innovative design approaches that optimize both internal and external product features. By reducing size and weight, companies can achieve more compact and efficient designs without compromising on functionality or performance, providing consumers with products that are both practical and cutting-edge.

Cost-Effective Solutions in Custom Hardware Development

While custom hardware solutions can seem costly at first, they often lead to cost savings in the long run through improved performance, reduced maintenance, and greater longevity. By investing in tailored solutions, companies can avoid the pitfalls and inefficiencies associated with using inappropriate or suboptimal components.

Streamlined Design Process

By working with experienced hardware design services, businesses can streamline the design process to avoid costly mistakes and ensure a faster time-to-market. Experienced designers can anticipate potential challenges and address them proactively, minimizing delays and additional expenses. This expertise is especially valuable in complex projects where precision and reliability are non-negotiable.

Additionally, a streamlined design process allows for faster iterations and adjustments, enabling companies to respond quickly to feedback and evolving project requirements. This agility can be a crucial factor in bringing products to market successfully and efficiently, maximizing the return on investment.

Material Selection

Choosing the right materials for custom hardware is crucial for cost-effectiveness. Designers can select materials that provide the necessary strength and durability without unnecessary expense. By evaluating factors such as environmental conditions, load requirements, and lifespan, designers can make informed decisions that balance performance with cost.

Furthermore, advancements in material science have expanded the range of options available for custom hardware solutions. Companies can take advantage of new materials that offer superior properties, such as increased durability, reduced weight, or enhanced thermal management, to create high-performing and cost-effective solutions.

Efficient Prototyping and Testing

Rapid prototyping and thorough testing are key components of cost-effective custom hardware development. By iterating quickly and testing rigorously, companies can identify potential issues early, saving time and resources in the long run. Prototyping allows designers to evaluate the functionality and performance of hardware in real-world conditions, ensuring that the final product meets all specifications and requirements.

Effective testing processes can also help mitigate risks associated with product failures or defects, which can be costly and damaging to a company's reputation. By investing in comprehensive testing, companies can ensure that their custom hardware solutions are reliable, robust, and ready for deployment.

Partnering with Hardware Design Services

To successfully implement custom hardware solutions, partnering with expert hardware design services is essential. These services offer specialized knowledge and experience in crafting bespoke hardware components, which can be invaluable in navigating the complexities of custom design.

Expertise and Innovation

Professional hardware designers bring a wealth of expertise and innovative thinking to the table, ensuring that the custom hardware meets both current and future needs. Their experience with various technologies and industries allows them to provide insights and solutions that might not be apparent to less experienced teams.

Moreover, working with experts can lead to innovative approaches that push the boundaries of what's possible with custom hardware. By leveraging their knowledge and creativity, companies can develop solutions that are not only effective but also groundbreaking, setting new standards in their respective fields.

Collaborative Approach

Effective communication and collaboration are vital for the success of any custom hardware project. Working closely with hardware design services ensures that all specifications and requirements are thoroughly understood and addressed. This collaboration fosters a shared vision and mutual understanding, which are crucial for aligning the project goals with the final deliverables.

A collaborative approach also facilitates transparency and accountability throughout the development process, allowing stakeholders to stay informed and involved at every stage. This involvement can lead to better decision-making and a more cohesive final product that meets or exceeds expectations.

Quality Assurance

Reputable hardware design services provide rigorous quality assurance processes to ensure that the final product meets the highest standards of quality and reliability. Quality assurance involves comprehensive testing, validation, and verification to ensure that the hardware performs as intended under all conditions.

By prioritizing quality assurance, companies can reduce the risk of failures or malfunctions, which can have significant financial and reputational consequences. Investing in thorough quality assurance processes ultimately protects the company's interests and enhances the credibility of its products in the marketplace.

Real-World Applications of Custom Hardware Solutions

Custom hardware solutions are employed across various industries to address specific challenges and requirements. Here are a few examples:

Medical Devices

In the medical field, custom hardware is used to create specialized equipment and devices that cater to individual patient needs, enhancing the effectiveness of medical treatments. Customization allows for the development of devices that integrate seamlessly with patient care protocols, improving outcomes and patient satisfaction.

Additionally, custom hardware solutions in medical devices can improve diagnostic accuracy and therapeutic efficacy. By tailoring devices to specific medical conditions or treatment modalities, healthcare providers can offer more personalized and effective care, ultimately improving patient health and quality of life.

Aerospace

The aerospace industry relies heavily on custom hardware to meet stringent safety standards and performance requirements, ensuring the successful operation of aircraft and spacecraft. Custom components are essential for achieving the precision and reliability necessary for safe flight operations, particularly in challenging environments.

Custom hardware solutions in aerospace also enable the integration of advanced technologies, such as autonomous systems or next-generation propulsion, that enhance performance and efficiency. By developing bespoke components, aerospace companies can maintain their competitive edge and continue to innovate in a highly competitive industry.

Consumer Electronics

In the rapidly evolving consumer electronics market, custom hardware enables companies to create innovative products with unique features that set them apart from competitors. Customization allows for the development of devices with enhanced functionality, improved user interfaces, and cutting-edge designs that appeal to consumers.

Moreover, custom hardware solutions in consumer electronics can drive the development of new product categories or features, opening up new market opportunities and revenue streams. By staying ahead of consumer trends and technological advancements, companies can maintain their position as leaders in the industry.

Conclusion

Custom hardware solutions offer unparalleled precision, performance, and adaptability, making them an invaluable asset in today's competitive landscape. By choosing bespoke hardware, businesses can achieve a competitive edge, optimize operations, and pave the way for future growth. Whether you're in aerospace, medical devices, consumer electronics, or any industry with unique needs, custom hardware solutions can be the key to unlocking your project's full potential.

When standard parts won't cut it, investing in custom hardware solutions is a strategic decision that can lead to long-term success and innovation. Embrace the power of custom hardware and elevate your projects to new heights. Custom solutions not only address immediate challenges but also position companies for sustained success in an ever-evolving technological world. By prioritizing customization, businesses can create products that not only meet the highest standards of quality and performance but also exceed the expectations of their customers and stakeholders.