Exact-Match Replacement Hardware: Vital for Safety

Why Exact-Match Replacement Hardware Matters (and What Happens When You Don’t Use It)

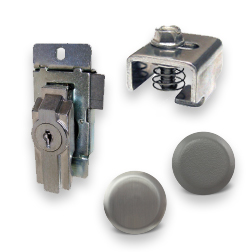

In the world of hardware solutions, precision is crucial. Whether you're a professional technician or a DIY enthusiast, using exact-match replacement hardware is an essential aspect of maintaining the integrity and functionality of your equipment. But why does it matter so much, and what can go wrong when you don't use the right parts?

When a piece of equipment breaks or wears out, the natural inclination is to replace the faulty part as quickly and cheaply as possible. However, opting for a non-exact match can lead to a cascade of issues. Exact-match replacement hardware ensures that your equipment functions as intended, maintaining performance, efficiency, and safety.

Compatibility and Performance

Using exact-match parts guarantees compatibility with existing systems. This compatibility is crucial for performance, as even minor deviations in size, shape, or material can affect the overall operation of the hardware. A mismatch could result in reduced efficiency, increased wear and tear, or even complete system failure.

Safety Concerns

Safety is another vital factor. Exact-match parts are designed to meet specific safety standards and regulations. Substituting with an incompatible part could compromise these standards, putting users at risk of injury or damage to other components. By ensuring that the replacement hardware matches exactly, you maintain the safety features that were originally engineered into the system.

What Happens When You Don’t Use Exact-Match Hardware?

Opting for non-exact match parts might seem like a cost-effective solution initially, but it often leads to long-term problems. Here's what you can expect:

Decreased Longevity

Non-exact parts can hasten the deterioration of equipment. Misaligned or improperly fitted components can cause excessive friction, leading to accelerated wear and reduced lifespan of the hardware.

Increased Costs

While the upfront cost of non-exact parts may be lower, the long-term financial implications can be significant. Frequent breakdowns and the need for additional repairs or replacements can quickly add up, negating any initial savings.

Operational Downtime

Incompatible parts can lead to unexpected equipment failures, resulting in operational downtime. For businesses, this downtime can translate to lost productivity and revenue. For individuals, it means more time spent on repairs rather than enjoying the equipment.

Making the Right Choice

The key takeaway is the importance of investing in exact-match replacement hardware from the start. It not only ensures optimal performance and safety but also saves time and money in the long run. When it comes to keeping your equipment in top condition, cutting corners is not worth the risk.

In conclusion, always prioritize exact-match replacement hardware to maintain the integrity and longevity of your equipment. Your future self—and your wallet—will thank you.